New microscope tool delivers rock-solid online alternative to in-lab experience

From the beginning, the bedrock of Earth sciences often relies upon the observation of in-hand specimens. In the field of petrology for example, research involves making very, very thin slides of rock (~30 microns) and looking at specimen samples through a microscope.

The onset of the COVID-19 pandemic last spring created a significant barrier to this long-standing practice when shared facilities, such as microscope labs, were off-limits to all but essential employees, and instructors had to quickly pivot to online courses with very little time to prepare.

This online-only instruction prompted Michigan State University geologist Tyrone Rooney and Ph.D. student Alex Steiner, who is part of Rooney’s MSU Geochemistry & Petrology Group, to begin talking about how to provide an accessible solution for creating and delivering microscopic educational materials to students.

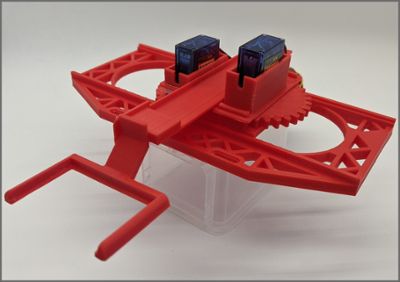

Their collective efforts resulted in the creation of an openâ€source device known as the PiAutoStage system that combines a 3-D—printed mechanism and an integrated camera, both of which are controlled by a central computer. The low-cost device permits the conversion of laboratory courses to an online format, providing an equivalent in-lab experience to the student. A paper explaining the system and how to build and use it was recently published in the American Geophysical Union journal, Geochemistry, Geophysics, Geosystems.

“The challenges we experienced in attempting to deliver this material online during spring semester compelled us to meet and start thinking about how to improve the experience,” Rooney said. “We reviewed the course material and asked: what were the things that worked, what were the things that didn’t work, and how could we make it better moving forward.”

Commercial solutions were expensive, so Rooney and Steiner began figuring out how they might offer something more cost-effective.

“For fun, I play with 3-D printing, which basically works in a grid,” Steiner said. “That led me to think, if 3-D printers move around in a grid, then why can’t we move a rock sample around in a grid underneath our microscopes? With that idea in mind, we worked to create a device that would move the section around for us. We went through a few iterations until we found a little drawing machine online that looked as if it could do exactly what we wanted it to do. We put it on the microscope, and it started moving around the way we hoped. That was really exciting.”

“It was a huge team effort,” Steiner added. “I focused on the actual mechanics of the machine and how to get it to work in the space we needed it to; Tyrone did the computer work, got the computer codes talking together and figured out a time-efficient way to stitch together all of the images. Getting the mechanics and the image processing both working efficiently is what made this successful.”

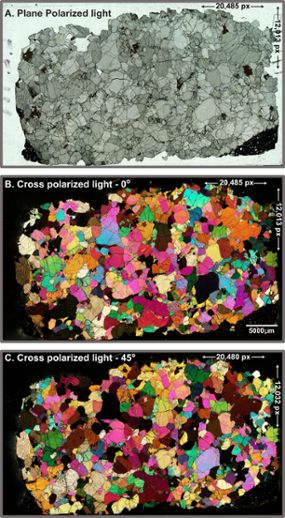

The system permits an experience comparable to using a microscope and has the added benefit of allowing students to examine, not only the field of view permitted in a microscope, but an entire sample at once. PiAutoStage can capture the entire area of a microscope slide in a series of overlapping images, which can then be stitched into a single high-resolution mosaic image.

This innovation provides a new avenue for instructors to create and deliver online microscopic content that more closely reflects their existing lab courses. In addition, the solution fully integrates with any web server, even university’s online learning management system, D2L, and works on a desktop or phone.

“This makes it a one-stop place for students,” Rooney noted. “They don’t have to get new software; they just use D2L.”

“As we started working with this new technology, it became evident that it was also critical to ensure that undergraduate students doing grant-funded research could continue their work during times that they couldn’t access microscopes,” Rooney said. “Alex and I are currently working on an NSF-funded project to explore the geochemical characteristics of lavas in east Africa. The only way to keep the grant going was to invent a way to get the microscope images to our students who couldn’t do any work without them. Thus, the teaching issue and the research issue for undergraduates became part of the same problem, and we saw it as worthwhile to spend time to try and solve both problems with the same device.”

So far, Rooney has used the PiAutoStage system to deliver content to two of his classes at MSU—GLG 361 (Igneous and Metamorphic Petrology) and GLG 862 (Advanced Igneous Petrology). The device is also being used at the University of Puerto Rico, and faculty at several other institutions—the University of Western Georgia, Wayne State University, and the University of Hawaii at Manoa—have expressed interest in the technology and how to build it.

The solution is designed to work on any microscope—geologic, biologic, etc., and the design permits the building of a stage for less than $250 and about a day of work. No further costs are necessary as the software used is all open source.

As PiAutoStage is rolled out and used by other institutions, Rooney and Steiner hope that people will help improve on and contribute to it.

“Because this is an open-source tool, the whole point is to try to make it better, to improve the user interface, and to create new versions of the tool that better fit specific microscope brands,” Rooney said. “Further, finding a way to digitize microscope slides effectively and at a reasonable cost will change the way we interact with this most fundamental part of our science upon which many other complex aspects are built.”

Details on the PiAutoStage are available through the peer-reviewed AGU paper listed earlier and the PiAutoStage website, https://sites.google.com/msu.edu/piautostage/home.

Banner image: This image was captured in cross-polarized light of a crystal rich lava from northern Kenya. The lava contains abundant, chemically zoned clinopyroxene crystals that record a history of magma interactions. Credit: Steiner and Rooney (2021), https://doi.org/10.1029/2021GC009693